-

2021

Begin of the Project

Approved by the DAS and DAT IN2P3

-

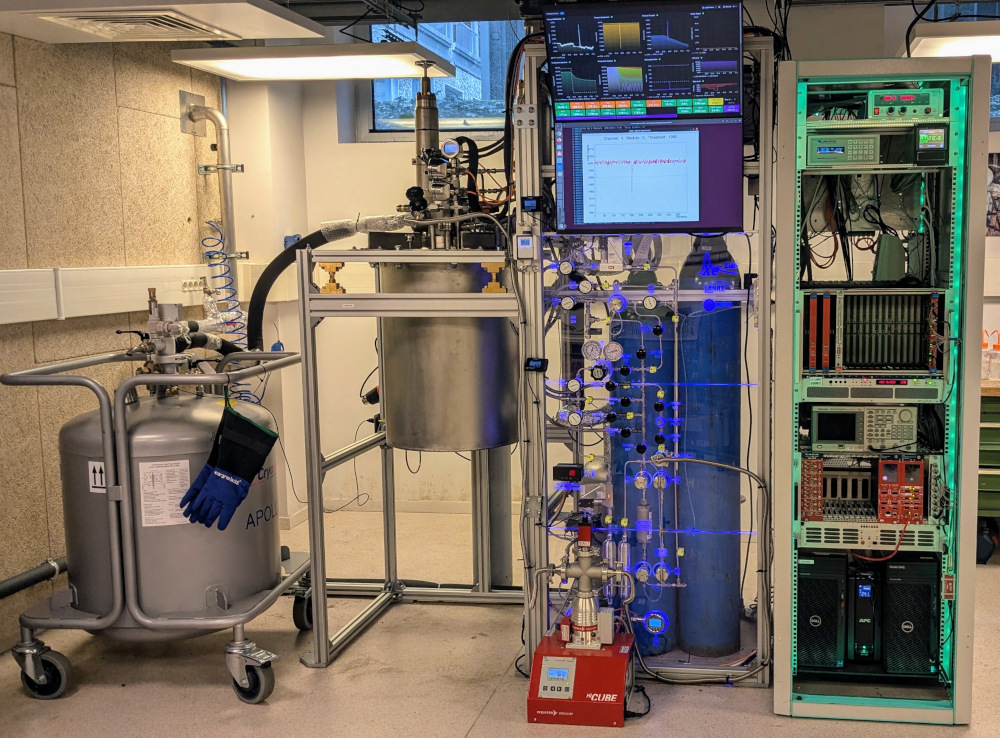

2024

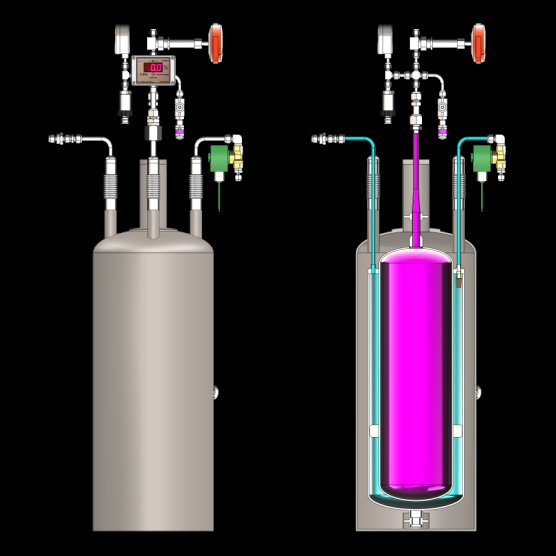

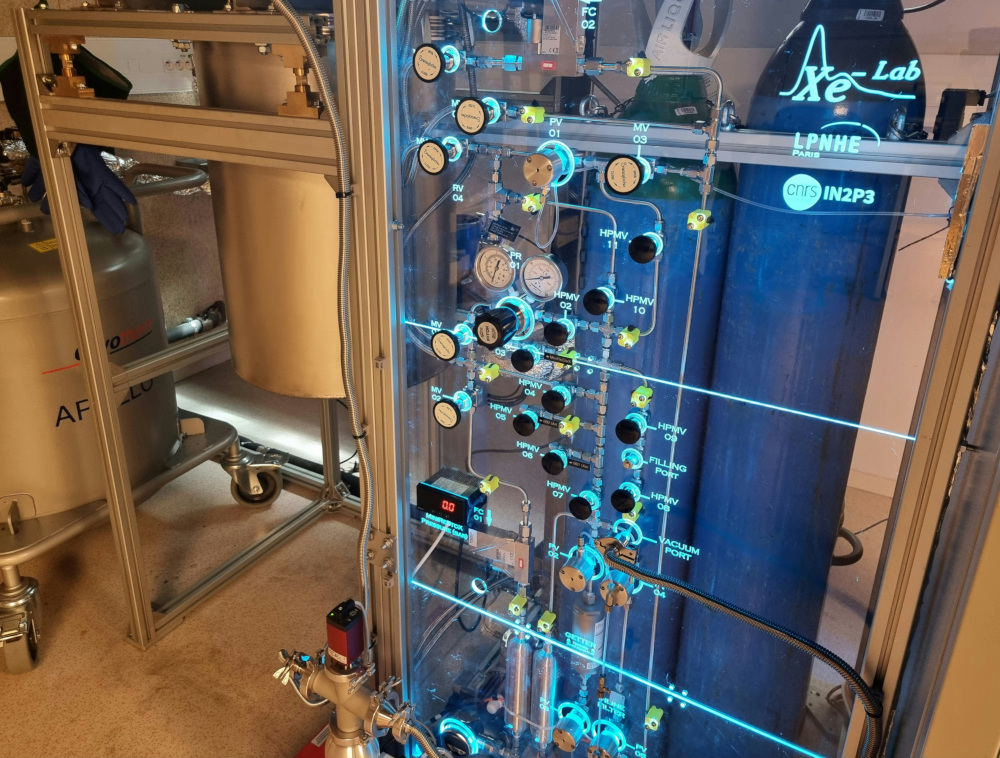

Cryogenic system completed

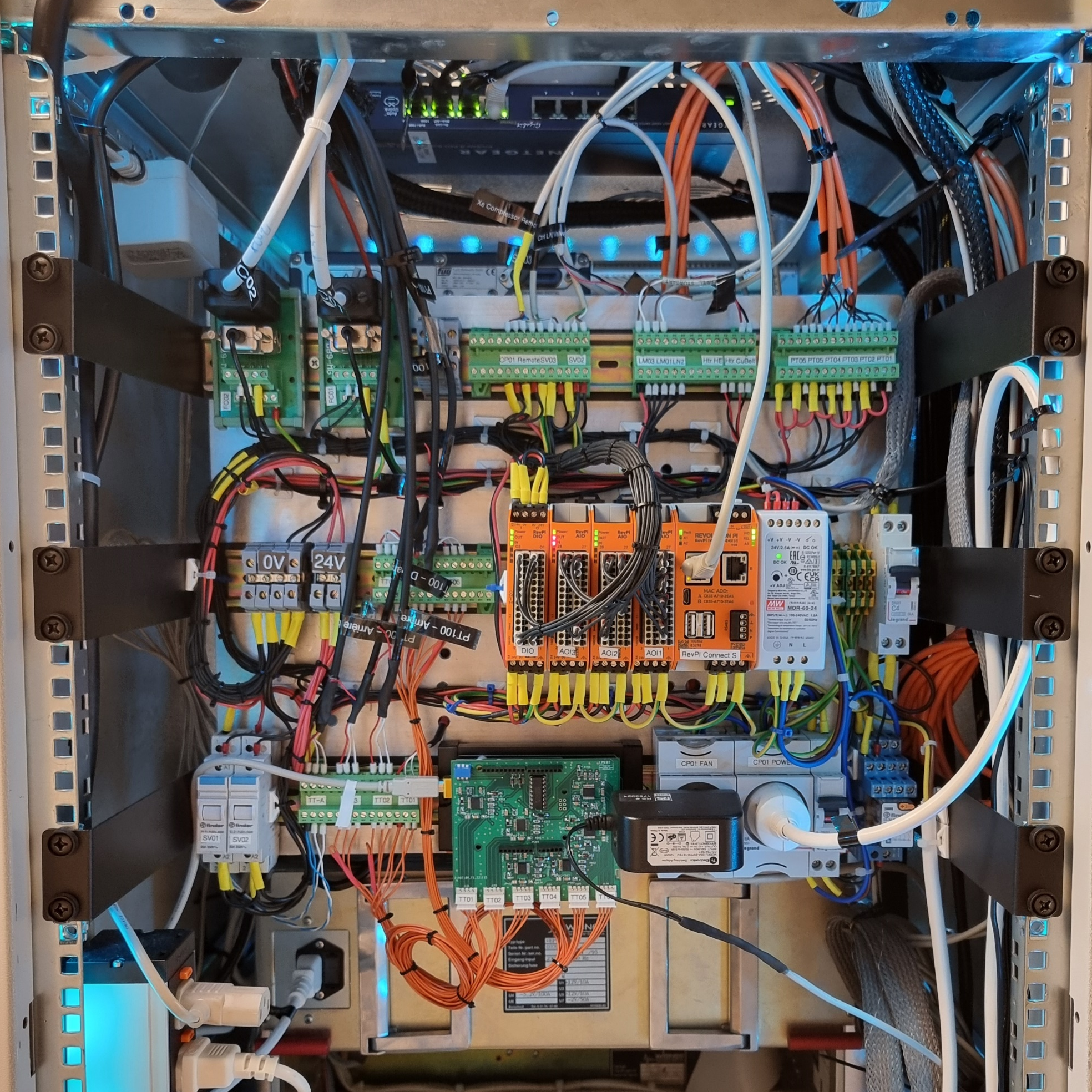

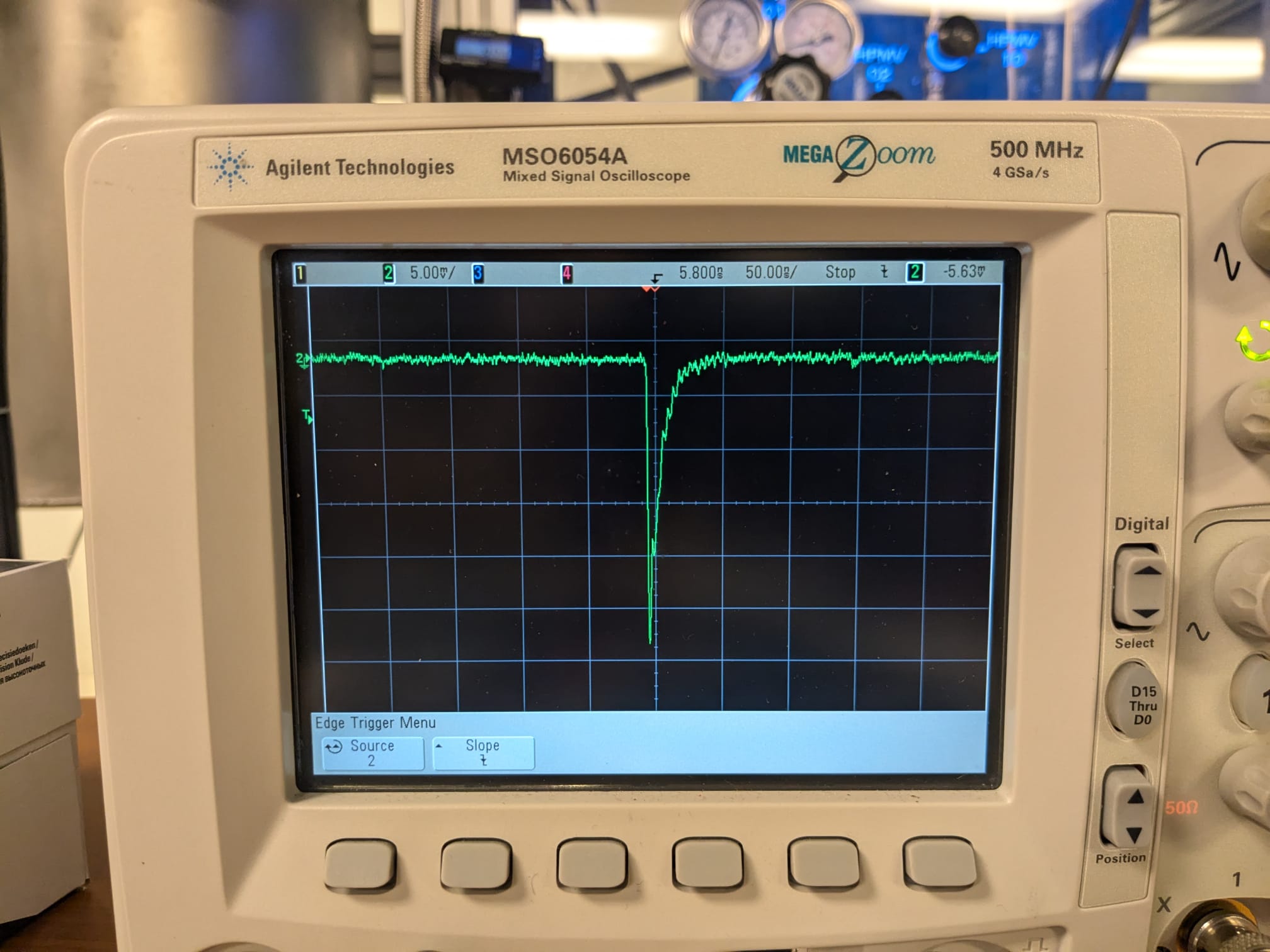

Cooling system, Slow Control, HV, DAQ

-

2025

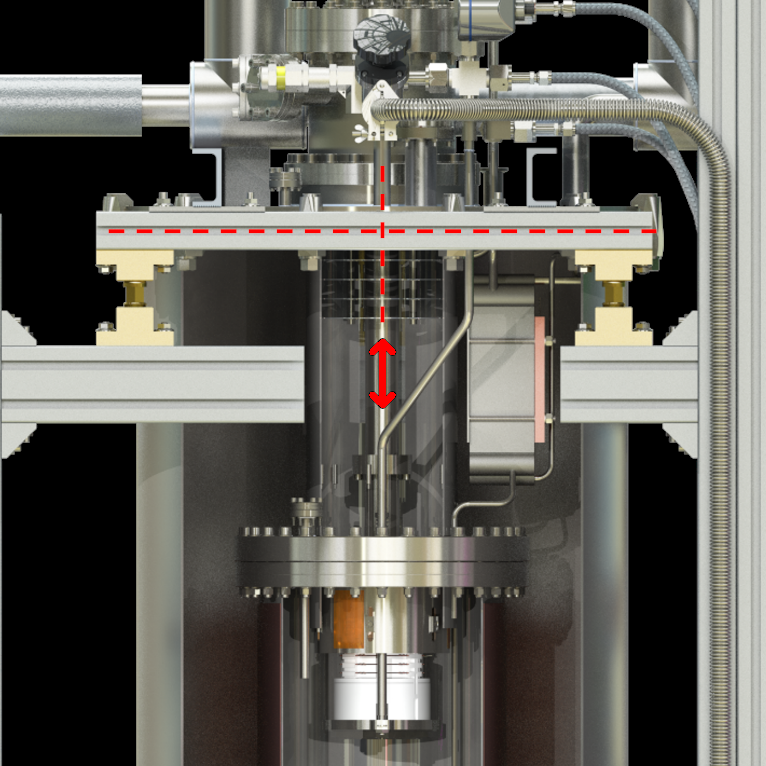

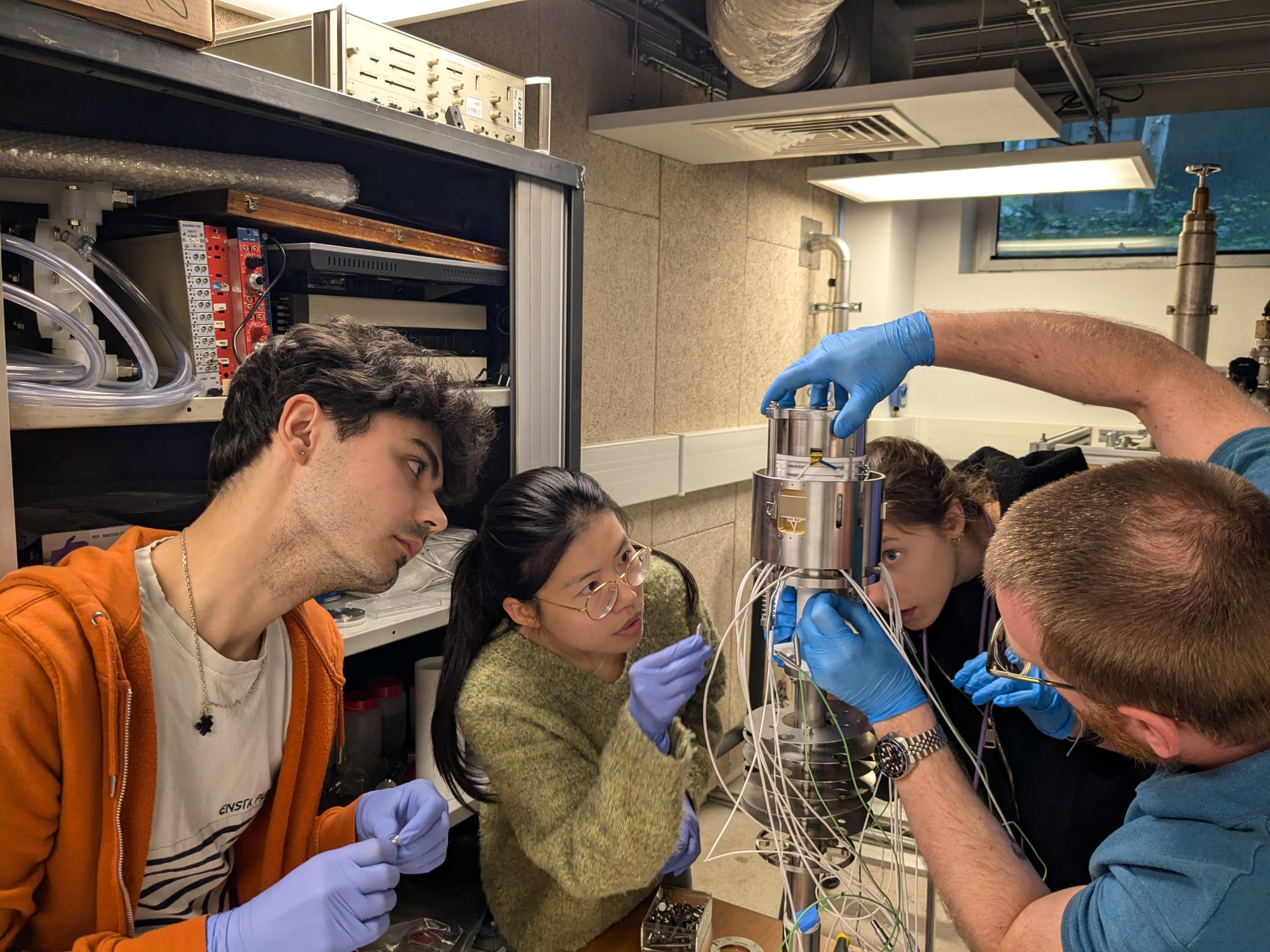

TPC completed

TPC, Leveling System, Begin of Calibrations

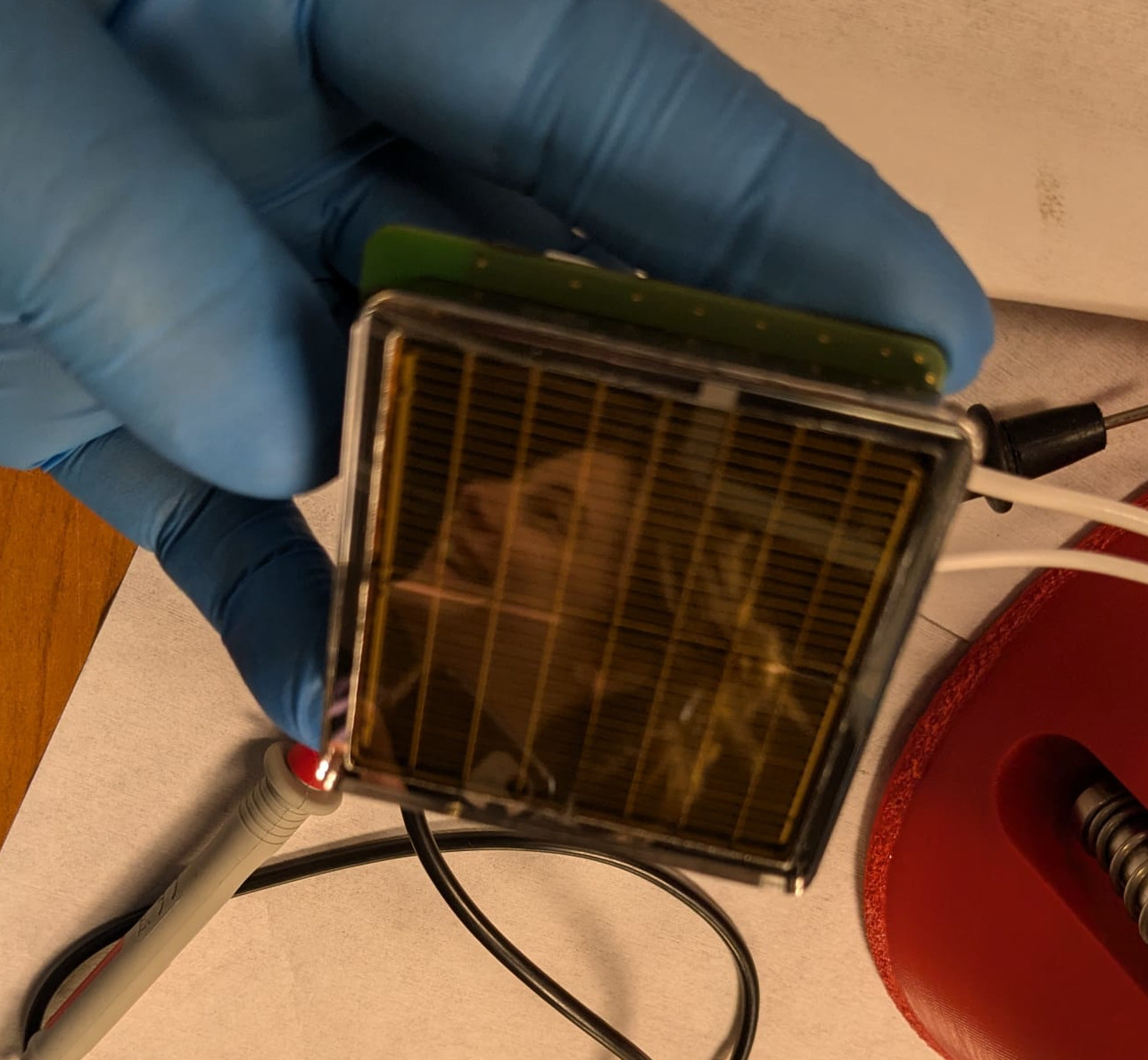

Begin of R&D on electrodes

The Project

XeLab is a cryogenic setup able to host liquid xenon TPCs. It has been created to develop and test new solutions for producing the proportional scintillation signal, with the ultimate goal of improving the performances of next generation dark matter detectors.

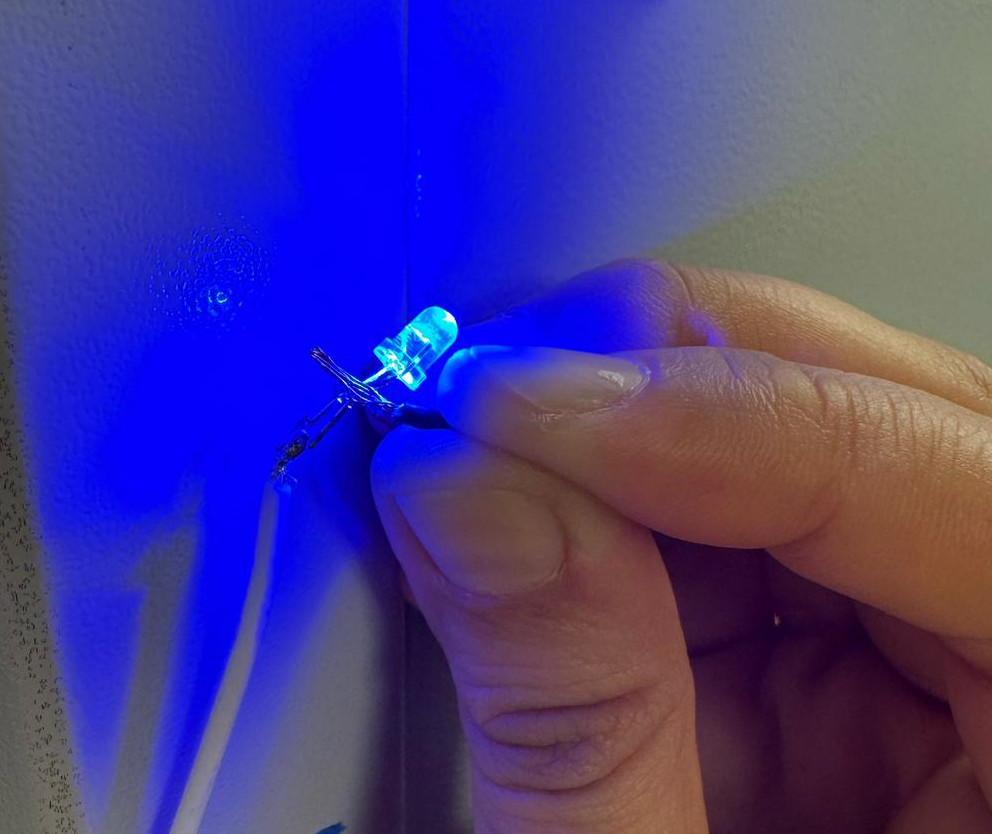

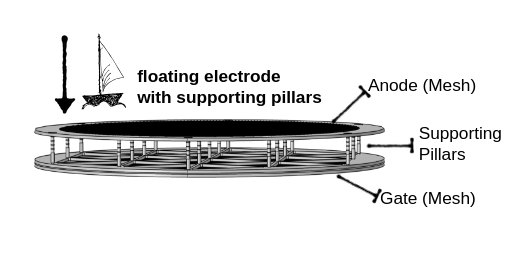

Xenon is all around us, it's a rare gas present in the air that we breath (less than one atom over ten millions). Extracted from the air, and liquefied at low temperatures (about 110 degrees below zero Celsius), it's a great material for particle physics. Xenon has been largely used to build, over two decades, the best detectors to hunt the most mysterious particle in our Universe that physicists look since a century: the Dark Matter. How can liquid xenon be used to detect a particle? Simply, think about a cylinder, full of liquid xenon. A particle, scattering on a xenon atom, deposits a certain amount of energy. Measuring this deposited energy allows physicists to better investigate the nature of that particle. One of the ways to measure this energy is by counting the number of electrons that have been torn from the xenon atoms surrounding the scattering point. This is done by a Time Projection Chamber (TPC): an electric field drifts all electrons towards the top, to be detected. A dual-phase TPC lets the electrons to approach the liquid-gas surface and to be extracted into the gas phase with a much higher field (several kilo-volts per centimeter). The electrons accelerate, scatter through xenon atoms and produce photo-luminescence at a high rate. The light is detected by photo-detectors. The light produced is therefore proportional to the number of electrons, that was in turn proportional to the energy deposited by the scattered particle. In order to generate such a high fields, the TPC must have two electrodes: the gate, close to the liquid-gas surface, as transparent as possible to let the electrons to pass through; and an anode, with a much higher potential with respect to the gate. With the new generation of dark matter detectors becoming bigger and bigger, those electrons are having in turn larger and larger diameters. And here it comes the issue. Gravity and electrostatic induction are both responsible of electrodes sagging, jeopardizing the performances of the TPC. The first goal of XeLab is the development of a novel twin gate-electrode that gets rid of this issue, thanks to a new concept: a gate floating on liquid xenon and connected to the anode by few vertical, insulating, pillars.